CAM Aligner System

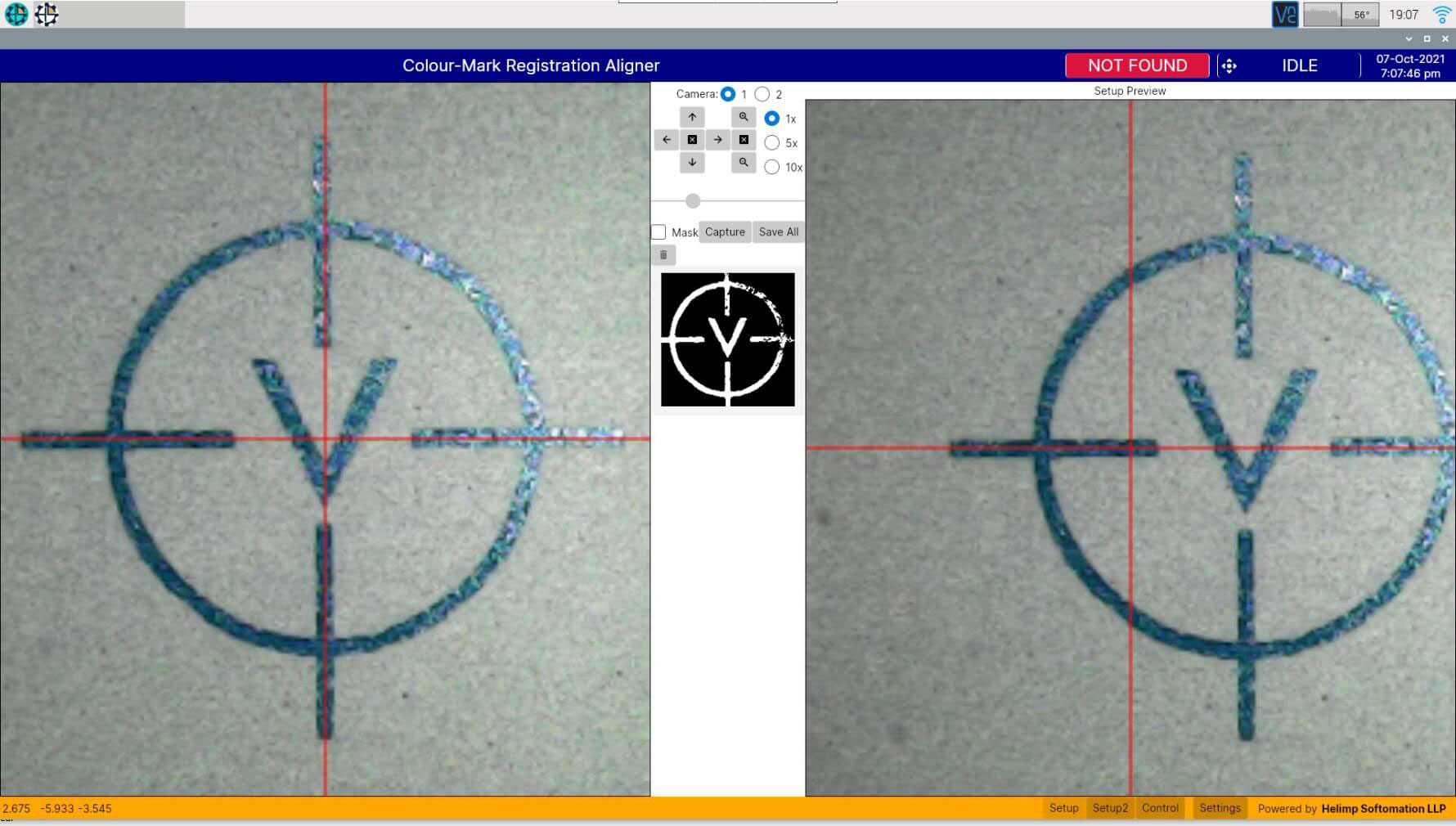

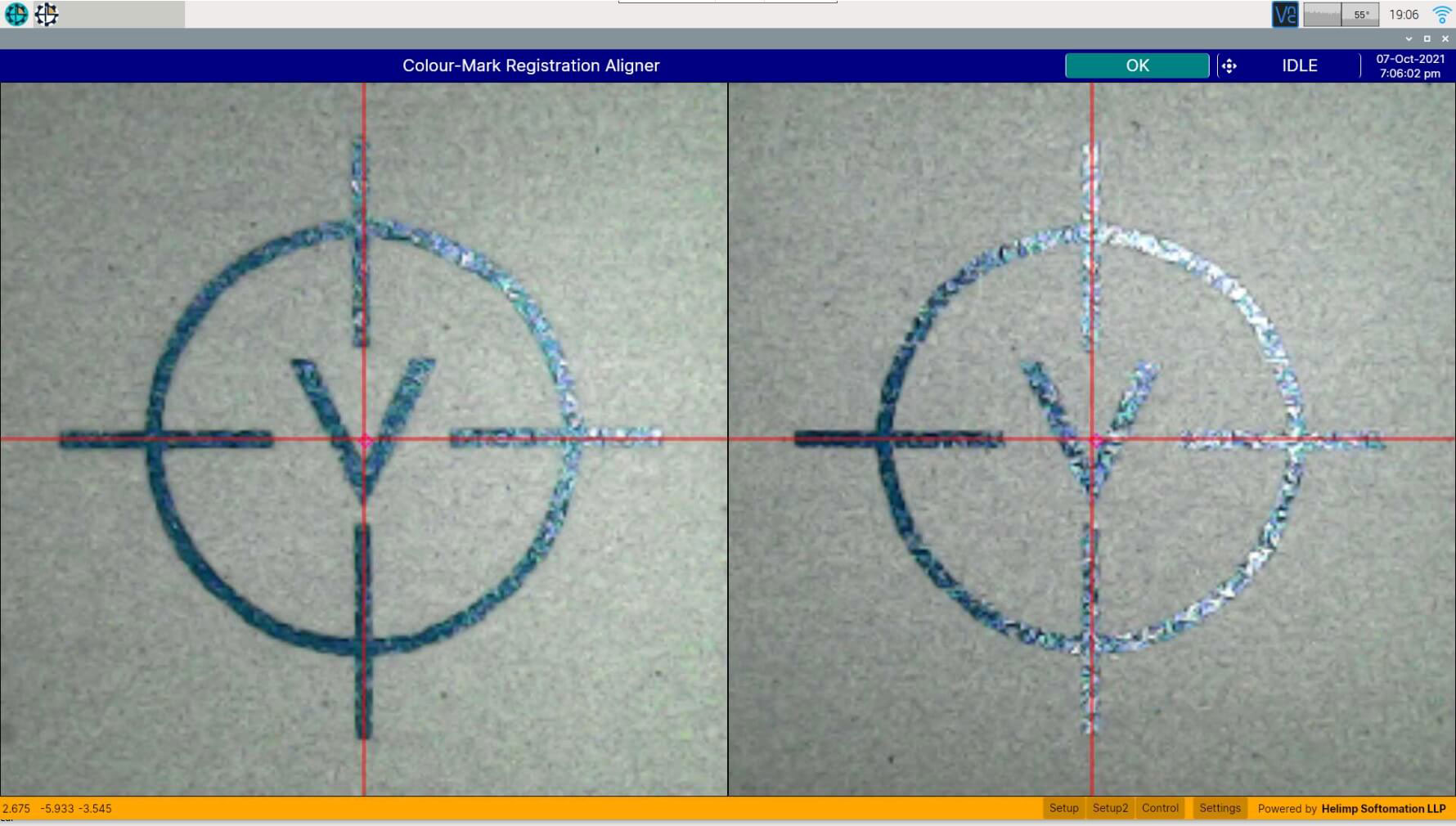

Automatic alignment system for printing industry to align the plate before punching on it with the help of cross-marking on it. Our image processing logic detects cross-mark using dual camera located on the machine over the objective plate. Once marking has been detected, operator can perform alignment operation by single button press.

CAM Aligner

- One shot alignment operators motorized positioning stage to get cross-marking in accurate center of the screen. Once alignment finished, automatic punching will be taken place to finish operation and operator can remove the plate thenafter.

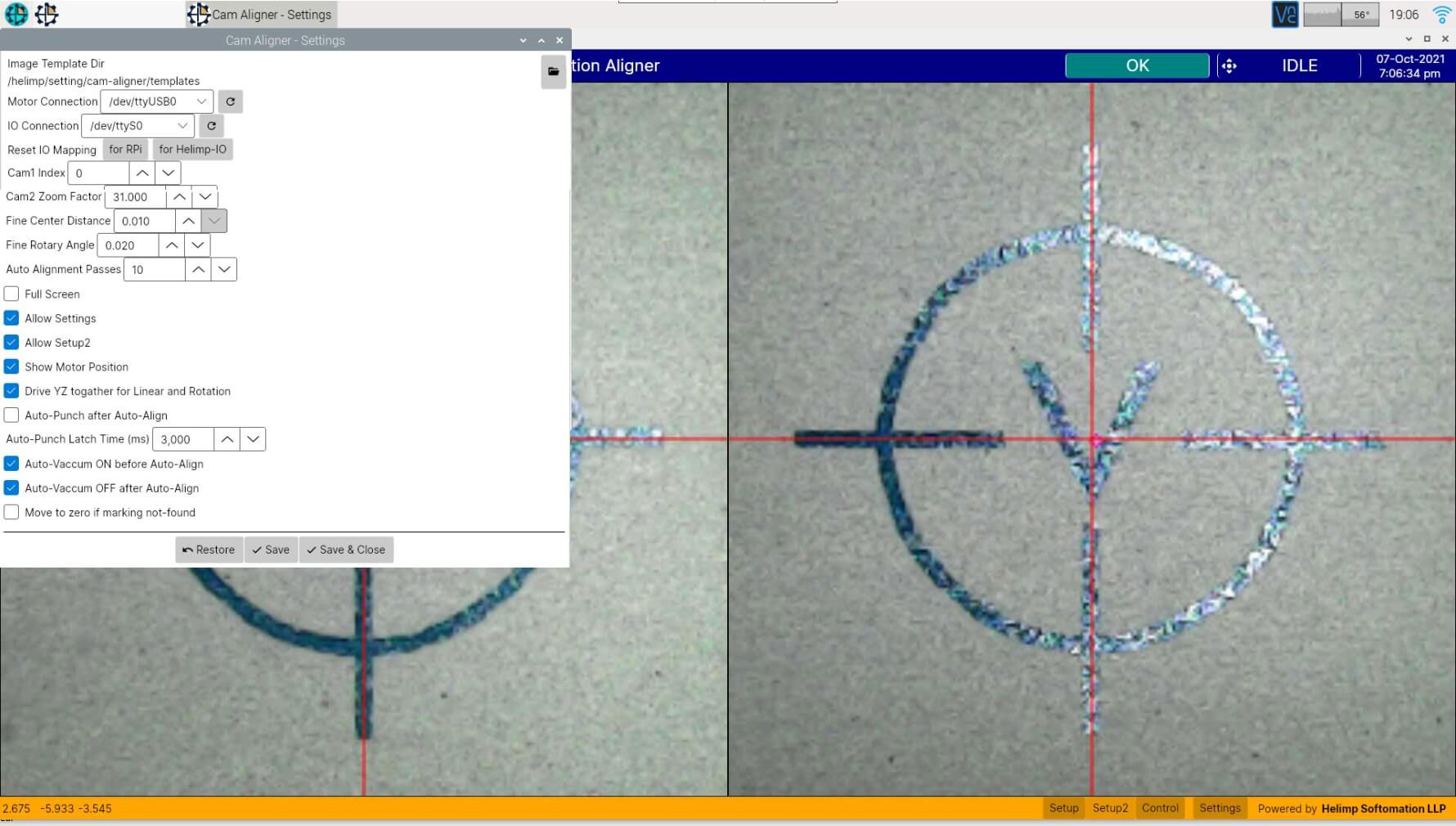

- Various marking identifier can be defined anytime to detect ideally any kind of shape accurately. There has to proper lighting be applied on the objective plate and enough contrast marking should be there to identify it.

CAM Aligner Features

Advanced CAM alignment technology with automatic precision control and user-friendly interface.

Fully Automatic

One shot automatic alignment process using state of the art marking detection and motion controller.

Friendly Software Interface

Operator friendly software interface equipped with dual camera live vision, machine status indicator, motor position indicator, mark setup panel, operational settings panel, etc.

Hybrid Controller

Our electronics control box is equipped with dual micro-controller subsystem. One handles XY and Rotary stage positioning, the other handles high-quality graphical rendering.

Operating Panel

Machine operating control panel with push-buttons and selector switches for both automatic and manual operations.

Technical Data

Logic

Customised as per machine mechanism

Operational Control

Main Panel controls (push button, selector switch, indicators)

Control Output

Relay output for punch and solenoid

Motor Control

Servo or Stepper motor using external driver

Power Supply

24v DC